Understanding Concrete Grinding and Its Benefits in Birmingham

Concrete grinding is a crucial process in the construction and maintenance of durable, attractive, and functional floors. In Birmingham’s diverse architectural landscape, ranging from commercial offices to residential developments, the demand for high-quality floor finishes is continually growing. If you’re seeking reliable solutions, concrete grinding Birmingham offers expert services that transform existing surfaces into smooth and polished assets. This process not only enhances aesthetics but also extends the lifespan of concrete floors, making it a valuable investment for property owners and contractors alike.

What is concrete grinding and why is it essential?

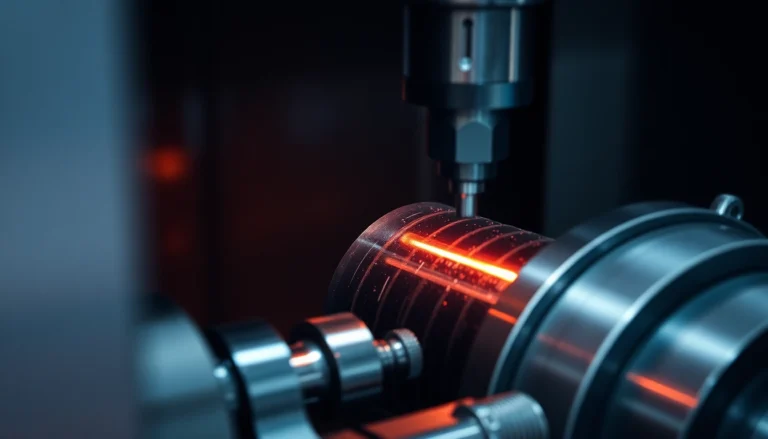

At its core, concrete grinding involves removing imperfections, coatings, or surface irregularities from a concrete slab using specialized machinery equipped with diamond abrasives. This technique is essential because it prepares the surface for further treatments like polishing or sealing, ensures safety by eliminating trip hazards, and improves the overall appearance of the floor. In Birmingham, where many historical buildings and modern commercial complexes coexist, proper concrete grinding ensures that floors meet safety standards while maintaining aesthetic appeal.

Advantages of professional concrete grinding for commercial and residential projects

Engaging professional concrete grinding services in Birmingham guarantees numerous benefits:

- Enhanced Durability: Proper grinding removes weak or damaged layers, creating a solid foundation that resists wear and tear.

- Improved Appearance: Achieve a smooth, glossy finish that elevates the visual appeal of floors in retail spaces, offices, or homes.

- Cost-Effectiveness: Regular maintenance via grinding extends the lifespan of your concrete, reducing long-term repair costs.

- Eco-Friendly Solutions: Minimizes the need for replacements by restoring older surfaces without demolishing structures.

- Safety: Eliminates uneven or cracked surfaces that could pose tripping hazards.

Key differences between grinding, polishing, and resurfacing

Understanding the distinctions helps property owners make informed decisions:

- Grinding: The process of removing surface layers or imperfections, often as a preparatory step.

- Polishing: Following grinding, polishing uses finer abrasives to produce a smooth, shiny surface with increased reflectivity and resistance.

- Resurfacing: Applying new toppings or overlays to repair or upgrade the floor, often involving a combination of grinding and coating techniques.

Choosing the Right Concrete Grinding Service in Birmingham

Factors to consider: experience, equipment, and certifications

Selecting a reputable contractor is critical for achieving superior results. Experience in Birmingham’s unique building regulations and logistical challenges is vital. State-of-the-art equipment, such as dual-head planetary grinders and HEPA dust extractors, ensure efficiency and safety. Certifications from recognized industry bodies signify adherence to quality standards, providing peace of mind that the project will meet or exceed expectations.

How to evaluate quotes and service guarantees

When comparing service providers, scrutinize their detailed estimates—be cautious of overly low bids which may compromise quality. Ask about warranties, maintenance advice, and whether they offer post-service support. A skilled contractor should stand behind their work with guarantees that cover potential imperfections or future repairs, ensuring your investment remains protected over time.

Common mistakes to avoid when selecting a concrete grinding contractor

Beware of:

- Choosing solely based on price without considering expertise or equipment quality.

- Neglecting to verify references or reviews from previous clients.

- Overlooking licensing and insurance, which can lead to liability issues.

- Ignoring the importance of tailored solutions for your specific flooring needs.

Step-by-Step Process of Concrete Grinding in Birmingham Projects

Initial assessment and surface preparation

The process begins with a thorough evaluation of the existing floor, identifying cracks, stains, or surface damage. Proper preparation involves cleaning the surface to remove dirt, oils, or coatings that might interfere with grinding accuracy. This preparatory step lays the foundation for a successful project, ensuring smooth operation and optimal results.

Grinding methodologies and equipment used

Professional contractors utilize diamond grinders of varying grit sizes. Coarse grits (30-40) remove imperfections quickly, while finer grits (80-150) achieve a smoother finish. The process may involve multiple passes, gradually refining the surface. In Birmingham, using environmentally friendly abrasives and energy-efficient equipment aligns with sustainable practices and reduces dust and noise during operations.

Finishing touches: polishing, sealing, and maintenance tips

Once grinding is complete, polishing with progressively finer abrasives creates a glossy and reflective surface. Applying sealants protects the floor from stains, moisture, and future damage. Regular maintenance, including sweeping and periodic resealing, prolongs the life and appearance of the surface. Expert advice from local Birmingham specialists ensures your floors remain durable and attractive over time.

Performance Metrics and Cost Considerations for Concrete Grinding

How to measure quality and durability of finished floors

Assessing the smoothness involves using specialized tools like profilometers or surface roughness testers. Durability can be gauged by resistance to stains, abrasion, and cracking over time. Engaging with trusted Birmingham service providers ensures adherence to industry standards, leading to long-lasting results.

Cost factors: size, complexity, and type of finish

Pricing varies depending on the size of the area, surface condition, and desired finish quality. Complex projects, such as layered overlays or decorative polishing, incur higher costs but deliver premium aesthetics. Asking for detailed, written quotes from multiple providers helps compare options and budget appropriately.

ROI and long-term benefits of professional concrete grinding solutions

Investing in professional grinding elevates property value, improves safety, and reduces ongoing maintenance expenses. Well-finished floors attract tenants or buyers and can generate increased revenues in commercial settings by presenting a polished, professional image. The long-term benefits justify the initial expenditure, especially when performed by experienced Birmingham specialists.

Future Trends and Sustainable Practices in Concrete Grinding Birmingham

Eco-friendly abrasives and energy-efficient equipment

Innovations include abrasives made from recycled materials and machines designed for lower energy consumption. These advancements reduce the environmental footprint of grinding projects in Birmingham, aligning with eco-conscious building mandates and corporate social responsibility goals.

Innovations improving finish quality and speed

Emerging technologies such as robotic grinding systems and multifunctional equipment accelerate project timelines and enhance precision. These tools minimize human error and produce uniform finishes optimized for specific aesthetic or functional requirements.

Integrating concrete grinding into green building standards

With sustainability at the forefront, Birmingham’s construction and renovation sectors increasingly incorporate green standards like LEED. Proper concrete grinding, when combined with recyclable materials and energy-efficient practices, contributes to achieving certification goals, making floors not only beautiful but also environmentally responsible.